FIVE Easy Ways to Save Money when Lighting a Cannabis Facility

1. Choose High Output Lighting

Higher power LEDs might cost more per unit, but you’ll need far fewer of them, making the room overall less expensive. And with fewer possible points of failure and easier installation, this design runs smoother. When looking at high power LEDs vs smaller ones, don’t compare fixture price; compare overall room price with other factors such as flexibility, quality of spectrum and length of the product’s rated life.

In this example you can see that cheaper isn’t always better, as weaker lights require more per room to meet brightness standards.

2. Get a Lighting Layout

Most LED manufacturers will do a computer simulation of your cultivation room for free. If you provide your exact room size and table or rack locations, these simulation softwares will find you the perfect arrangement of lights so you don’t over-purchase trying to fill the room. They’ll take into consideration walkways and locations of equipment, empty space, and canopy so you buy exactly the amount of lights you need, no more, no less.

3. Choose a Programmable Spectrum

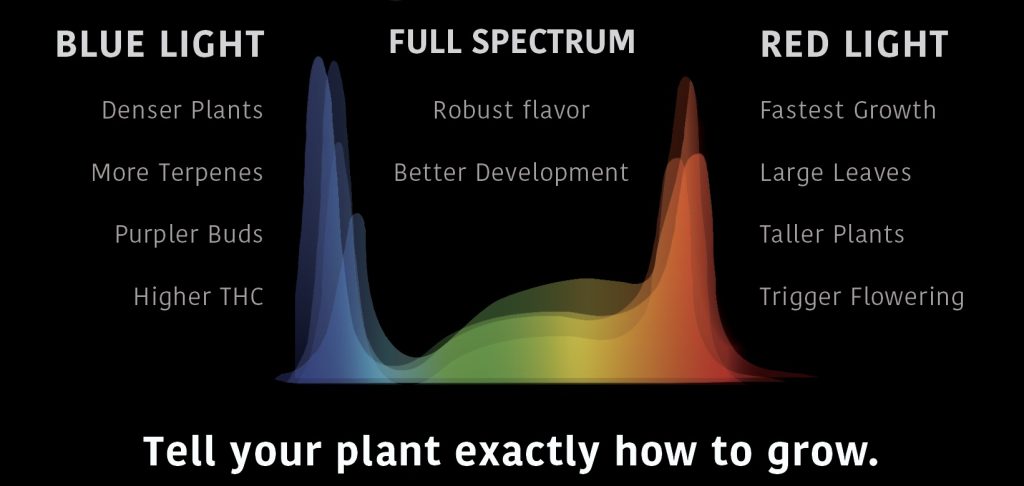

Another thing to consider is protecting your grow room against competing technology and methodology. As cultivation science advances, research into spectrum grows more and more precise. We know blue shortens internodal spacing for bushy, dense plants, and that red induces quicker flowering for more harvests per year. A programmable spectrum not only increases productivity by making the ideal spectrum for any stage or strain of cannabis just the touch of a button away, it also means you’ll be able to keep up with the latest trends.

For example, if the market demands purple buds, simply add a little blue to the end spectrum to trigger anthocyanin pigment production.

Replacing all the lights in a facility to stay competitive is a massive waste of money and time. A programmable spectrum light is more future proof and therefore a longer lasting investment.

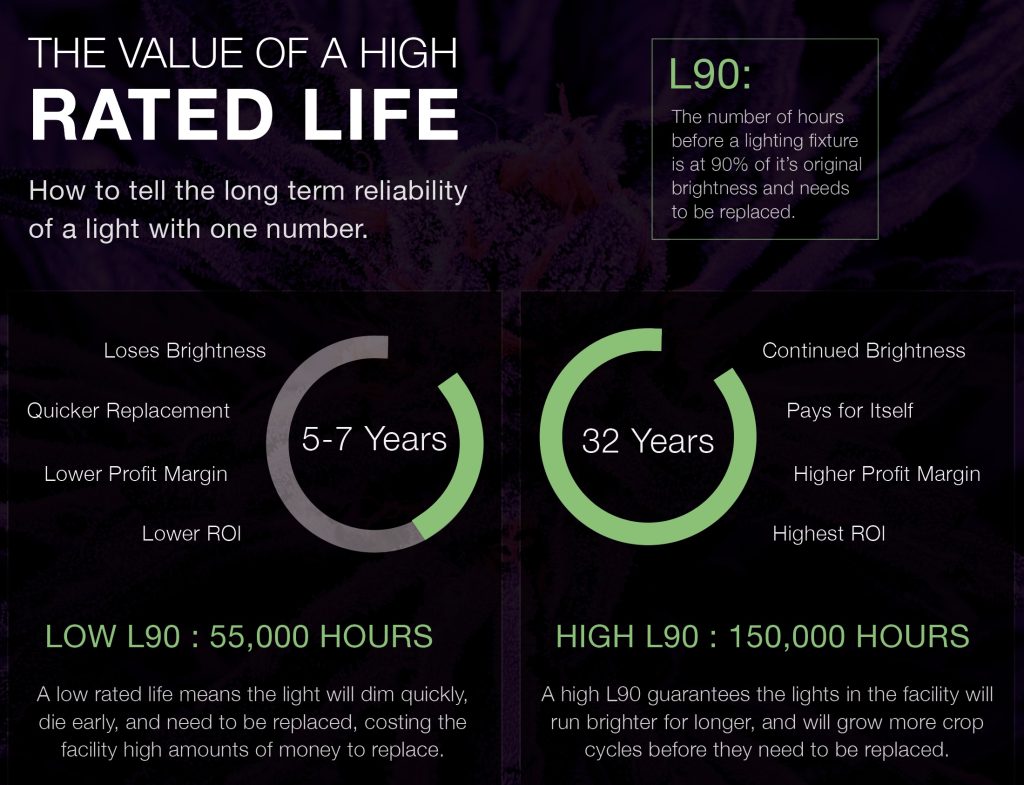

4. Get a Long Lasting Light

Speaking of long lasting, always check the rated life. Often shown as a ‘L90’, this number describes the number of hours until a light is at 90% of its original output and therefore needs to be replaced. It is a great measure of the reliability of a fixture, as it takes into account build and part quality. Unfortunately, most budget manufacturing LEDs are only rated for 50,000-55,000 hours. Try to find one that’s at least 100,000 hours to ensure a long lasting investment. A light with a poor L90 of only 55,000 hours will dim considerably in the first three years, leading to a reduction in product grown and a loss in profits.

5. Choose Energy Efficient Lights

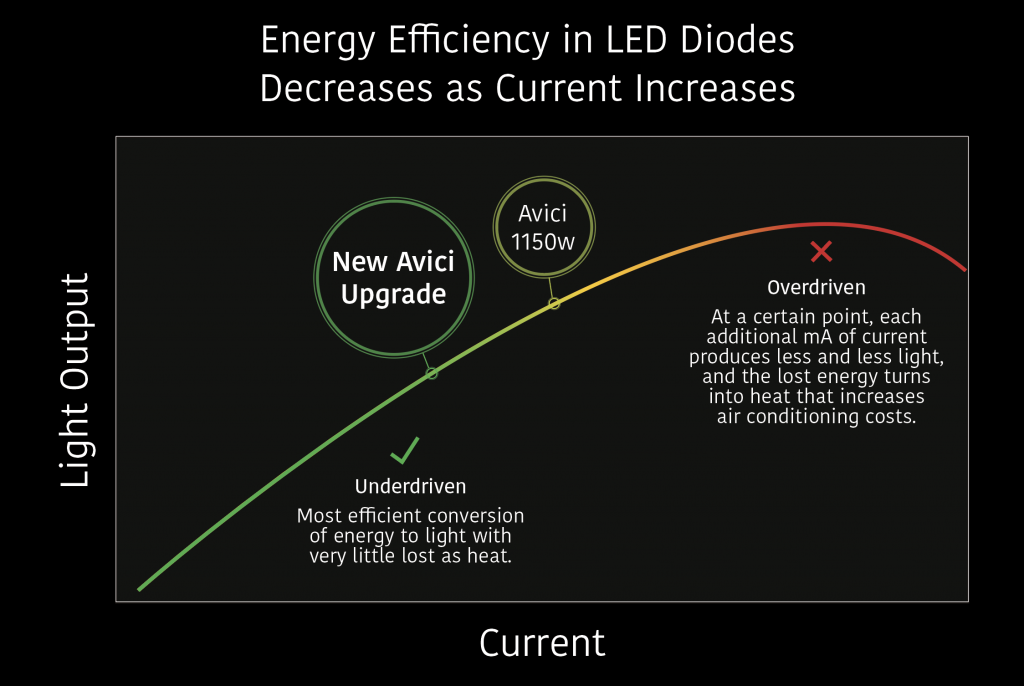

Highly efficient LEDs (something in the 2.8-3.8 range) save money not just on the initial drop in electrical costs, but also in air conditioning needs. Less efficient LEDs waste energy as heat, which then needs to be removed from the grow room. A high efficiency LED gives you double savings in both initial energy consumption and AC, which can be a considerable amount for larger grows.

Some LEDs, especially high powered ones, have a low rated life or energy efficiency due to overdriven diodes. That means they’re putting too much power through each chip, which results in a bright, but unreliable light.

In Summary

With a little design consideration and research, you can significantly lower your lighting costs without compromising on brightness and yield. You can even save money for your future self by choosing long lasting, future proof lighting. Here’s a simple checklist to get you started.